Custom EVA Boat Flooring Wholesale to Make Your Brand Memorable

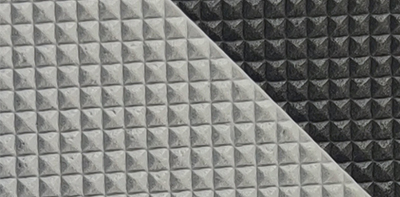

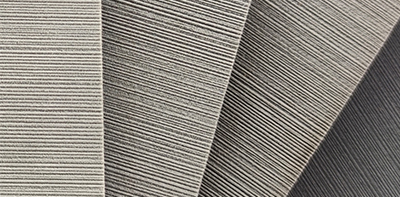

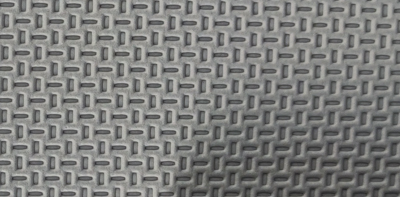

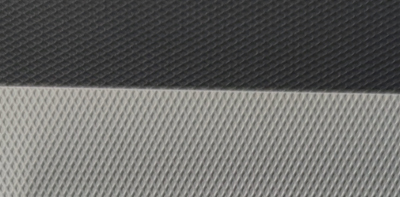

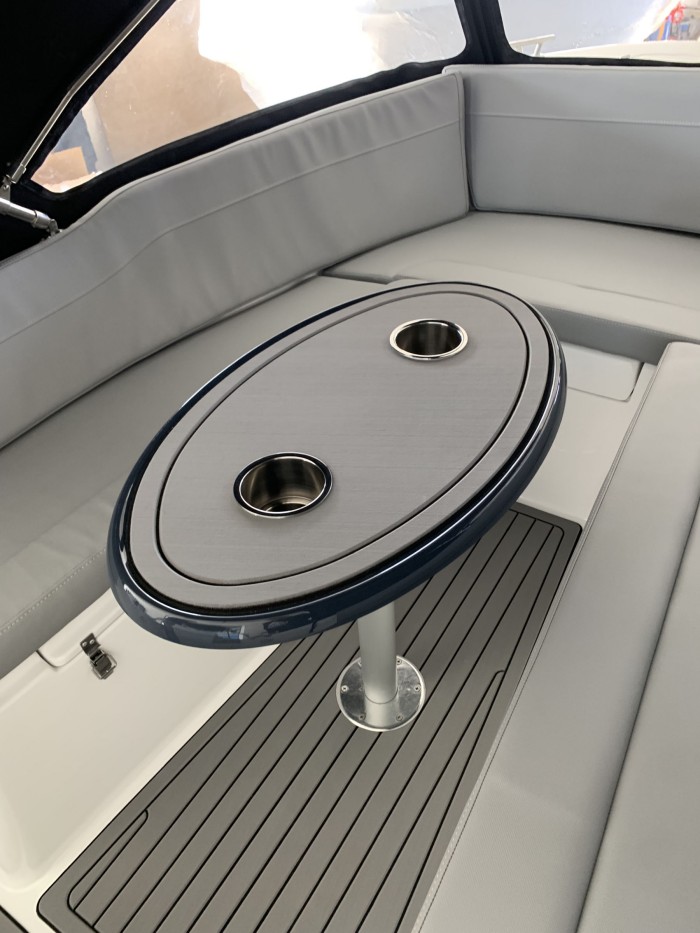

Choose from textures like diamond, T-pattern, Pebble, and Woven pattern, or use our custom texture EVA foam solution for special styles. Our marine-grade, closed-cell textured eva foam withstands water, UV damages, and put on, making sure long-lasting efficiency. Companion with a maker for much better pricing, regular quality, and trusted supply of artificial teak wood and other textured marine foam choices for boat foam decking.

Explore our wide range EVA Boat Flooring options

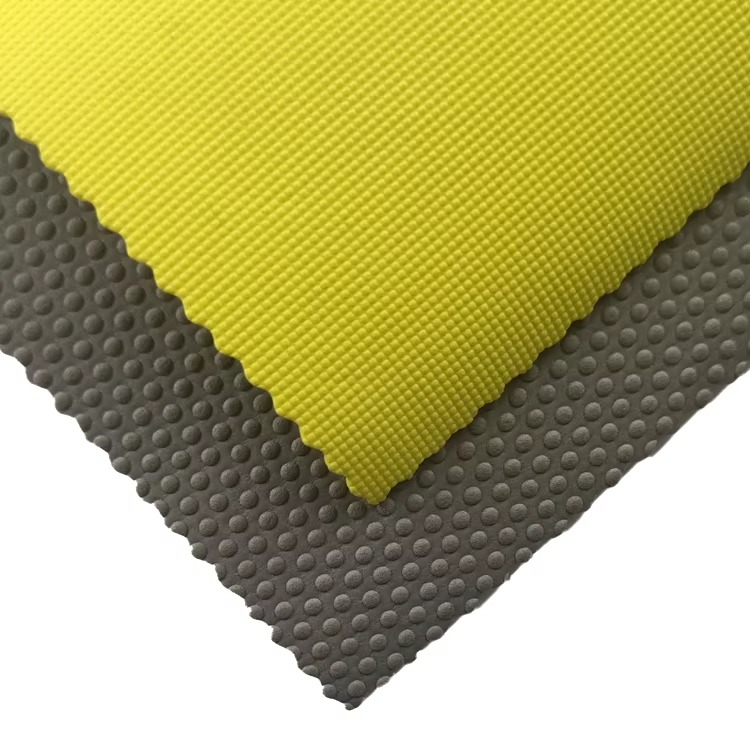

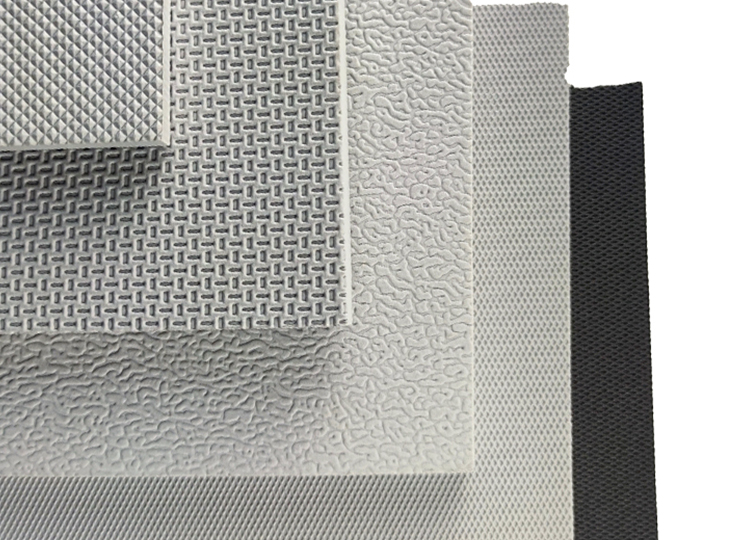

Choose your thickness, color, and texture – including popular options like Diamond, Dot, Brushed, T Texture, Pebble, and Fabric Woven, or leverage our capabilities for custom texture EVA foam designs – to perfectly match your brand’s unique specifications and client boat decking needs.

Diamond

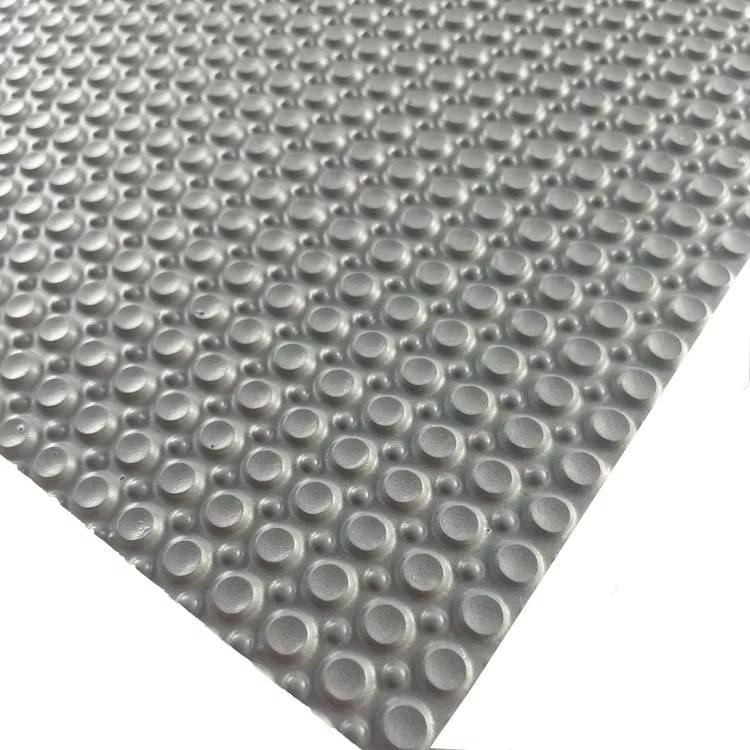

Dot

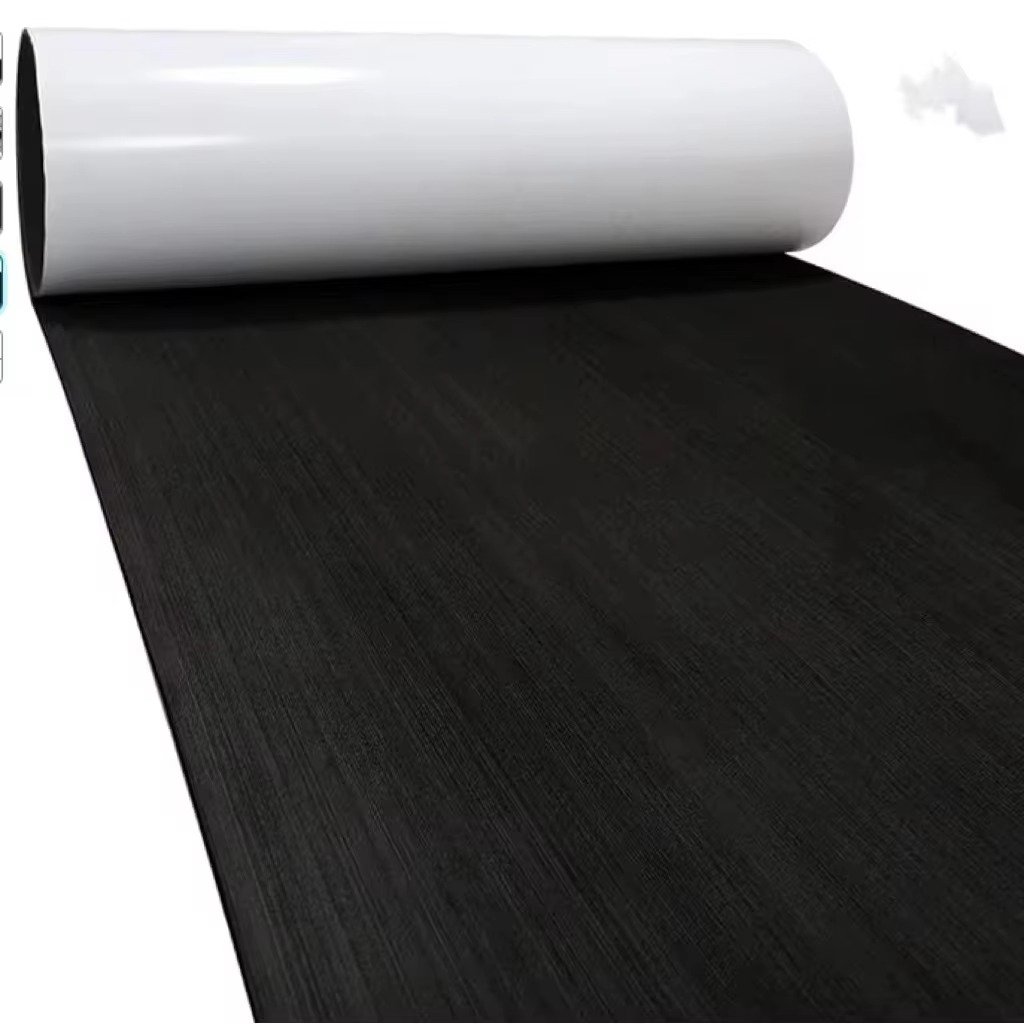

Brushed

T Texture

Pebble

Fabric Woven

Custom Texture of eva boat flooring Sheets for for All Occasions

We offer a wide range of sheet sizes and premium 3M back glue (PSA) options for diverse applications, from boat decking and helm mats to pool and golf cart flooring. Our skilled staff are experts in custom texture EVA foam and can assist your team in selecting or developing the ideal textured marine foam to meet your specific production and branding requirements, enhancing your boat foam product line.

- ✔ Boat Decking: Provide a comfortable, non-slip, and aesthetically pleasing surface with your unique textured eva foam designs.

- ✔ Helm Pads: Develop branded cushioning and stability solutions for captains.

- ✔ Swim Platform Pads: Offer safe and comfortable surfaces for boarding and exiting the water.

- ✔ Cooler Tops: Create non-slip, insulated surfaces that carry your brand’s unique texture.

- ✔ Fenders/Dock Bumpers: Produce protective solutions with enhanced grip.

- ✔ Kayak and Paddleboard Decks: Offer superior traction and comfort for watersports.

- ✔ Also perfect for non-marine uses: including custom swimming pool flooring and unique golf cart flooring solutions, expanding your market reach with specialized boat foam materials.

Source Your Custom Texture EVA Foam from China for Significant Cost Savings

In the section below, we’ve outlined some of the basic cost for our wholesale, closed-cell EVA marine foam sheets. However, please keep in mind that the final cost is dependent on the specific, customized service your workshop requires.

We understand that cost-effectiveness is crucial for developing new product lines. Our wholesale, closed-cell EVA marine foam sheets, including our custom texture EVA foam, are priced to offer significant savings, though final costs will depend on your specific customization requirements. Compared to other foams, our EVA is engineered for marine use and manufactured in China, providing substantial cost advantages for your business. Sourcing your textured eva foam from us ensures consistent density for your boat flooring products. We offer comprehensive custom boat foam options, allowing you to choose thickness, color, and PSA from 3M 99786 to 3M 9775, all meticulously matched to your unique brand specifications. As your marine flooring brand expands, we can reliably supply your textured marine foam needs from China. Trust our commitment to quality and competitive wholesale prices for all your custom boat foam decking requirements.

What Our Customers Have to Say

Frequently Asked Question

We’ve compiled the most frequently asked questions about our foam decking to help you make an informed purchase decision.

As the largest EVA foam manufacturer in China, we offer closed-cell EVA foam with significant advantages for boat flooring systems and for brands developing custom product lines:

Industry-Leading UV Resistance: Tested to withstand over 3000 hours of UV exposure, preventing fading and degradation. This significantly exceeds industry standards, protecting your brand’s reputation.

Durability: Resists wear and tear, providing long-lasting performance in marine environments, crucial for customer satisfaction with your textured marine foam products.

Unmatched Customization: We offer precise custom sizing (length, width), thickness, and unique textures to meet your exact specifications for your textured eva foam products.

Precise Color Matching: We can match any Pantone color to create the most popular and on-trend looks for your branded boat foam flooring.

Our standard EVA foam for boat flooring has a hardness of 55-60 Shore C. While some products on platforms like Amazon may use 45-50 Shore C, our higher-quality foam, similar to SeaDek, is formulated for greater durability. We can produce foam in other hardness ranges (Shore A or Shore C) upon request, but 55-60 Shore C is our recommended range. We use Shore C for our standard product.

Our EVA foam is manufactured in-house at our own production facility in China.

MOQ varies depending on the complexity of the custom texture EVA foam design. For custom Pantone colors and unique textures, the MOQ is typically 100 sheets per color/texture. For standard textures and sizes, please contact our EVA foam experts for specific textured marine foam MOQ information tailored to your project.

Contact our sales team via [email protected], or the “Get a Instant Quote” form on our website. Provide details about your requirements (foam type, thickness, density, color, sheet size, quantity), and we’ll provide a customized quote.

No, EVA (ethylene-vinyl acetate) foam itself is generally considered a non-toxic material. It’s a closed-cell foam that does not typically contain harmful chemicals like phthalates, heavy metals, or BPA (Bisphenol A), which are sometimes found in other types of plastics.

Custom EVA Boat Foam Resources and Articles

Explore our resources and articles below to learn everything you need to know about using EVA foam to enhance your boat. We provide expert information on selecting the right product, customizing it to your needs, and ensuring a successful installation.

Advantages of EVA Foam Boat Decking

EVA foam boat decking has revolutionized modern boating by offering enhanced comfort, safety, and protection.

How To Install Foam Decking On A Boat: A Step-by-Step Guide for Professionals

Are you looking to upgrade your boat’s flooring with comfortable, durable, and stylish EVA foam decking?

A Comprehensive Guide to Choosing High-Quality EVA Boat Deck Foam

EVA boat deck foam is an essential material for boat owners, offering cushioning, excellent grip, and safety-enhancing traction for any watercraft.

Custom Texture EVA Foam Sheets For Boats Ordering Process

Ordering custom EVA Foam Sheets from us is easy. With just six steps, you will get the best closed-cell EVA foam for your products.

Get a Wholesale Quote

We provide free, no-obligation quotes based on your specific EVA foam requirements (quantity, dimensions, material specifications, customization). Click the "Get a Quote" button or contact our sales team directly.

Request Samples

After receiving your quote, we highly recommend ordering EVA foam samples to verify material quality, color, texture, and adhesive properties before placing your full wholesale order.orld.

Place Your Wholesale Orde

Once you're satisfied with the samples, confirm your order details (quantity, specifications, delivery address) with our sales team.

Production Begins

We initiate production upon confirmation of your order and receipt of payment. We accept various payment methods, which will be detailed in your quote.

Rigorous Quality Inspection

After production, our quality assurance team meticulously inspects all EVA foam products to ensure they meet our stringent quality standards and your exact specifications before shipping.

Shipping and Delivery

We ship your order using your preferred method (air freight, ocean freight, or a combination). Please inform our sales team of any expedited shipping needs during the quoting process.

Get Started With Your Exclusive Custom Texture Marine Decking Line

Enhance your product offerings with our superior custom texture EVA foam marine decking materials. We provide comprehensive customization options, including unique colors, exclusive textures, and custom logos, all engineered to meet your exact specifications. Contact us today for competitive wholesale pricing and begin developing your exclusive textured marine foam product line.

Trend on eva foam sheets for boats (Closed-cell foam)

Discover the growing demand for our closed-cell EVA foam sheets in boat decking, flooring, and other marine applications. We offer popular and custom texture EVA foam options, providing the ideal textured marine foam to elevate your brand’s boat foam products.