OEM Boat Flooring & Custom Decking Kits for Your Brand

Reliable partner for your OEM boat flooring needs. We manufacture a wide range of custom decking kits, including helm pads and cooler pads, helping you deliver superior boat foam decking to your customers.

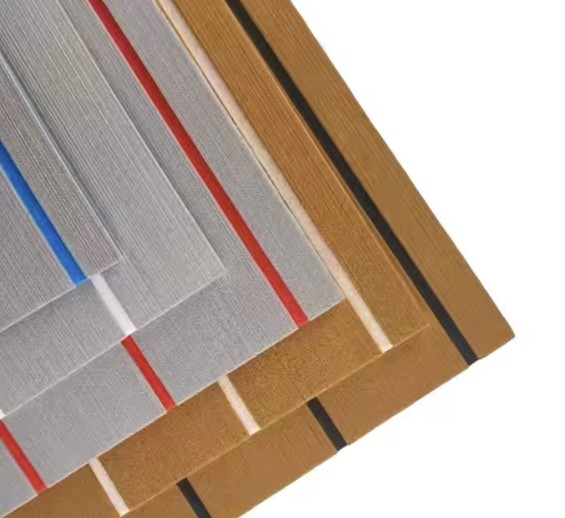

Wholesale CNC Routered Foam Boat Flooring ,helm pad And cooler pad

Provide your customers with superior boat flooring and enhanced boating experience with custom EVA foam decking and helm pad,cooler pad from our factory. We are a direct manufacturer, offering a complete foam boat flooring system solution.

The Value of Factory-Direct OEM Boat Flooring from China to Save Cost

In the section below, we’ve detailed some of the basic costs associated with our foam flooring for boats. However, please keep in mind that the final price is ultimately dependent on the specific customization and services you require for your vessel.

Unit Cost for Custom Decking Kits (OEM Pricing)

For a typical custom decking kit, hardness 55 to 60 shore C,with 3M adhesive that equal to Sedeck quality our cost is approximately $39 per piece. Our pricing may adjust depending on your custom adhesive (PSA)needs. Reach out to us for the exact pricing for your order

Sea Freight Shipping Cost

Your shipping costs for foam boat decking will vary depending on your delivery location. We offer pallet packing, box packing,please send your packing requirement and zipcode to get the cost.

Other Fees

Upon arrival at the port, your cargo will be cleared and dispatched. The associated cost for this varies and depends on the transportation distance to its final destination from the port

Your One-Stop Factory for OEM Boat Flooring

We provide a complete OEM service for all our custom foam boat decking products, helping you expand your market share. Rely on us for high-quality boat floor foam solutions that establish your brand and build customer loyalty.

.jpg)

Why Partner With Us For Your OEM Boat Flooring?

As a dedicated manufacturer of custom-designed, closed-cell foam flooring for boats, we serve the global marine industry. Our technology and OEM processes ensure precision CNC routering and consistent quality for every boat foam flooring order.

.jpg)

- Collaborative Design: We partner with you to design and produce custom decking kits that meet your brand's exact needs.

- Competitive Factory Pricing: Our direct-from-factory model for all OEM boat flooring orders ensures you get the best possible price.

- Global Logistics Support: We handle all international shipping and logistics, ensuring your boat foam decking products are delivered safely and on time, anywhere in the world.

- Certified Quality & Compliance: Our certified manufacturing processes and strict quality control ensure every piece of boat foam flooring we produce meets the highest industry standards.

What Our Customers Have to Say

Frequently Asked Question

We’ve compiled the most frequently asked questions about our foam decking to help you make an informed purchase decision.

As a direct manufacturer, partnering with us offers three key advantages. First, Cost-Effectiveness: You eliminate middleman markups, resulting in a more competitive price point for your business. Second, Ultimate Customization: You have direct access to our engineering team. This allows for deep customization not just in design, but in the material itself—we can adjust EVA density, hardness, color, and UV inhibitors to meet your exact specifications. Third, Quality Control: We oversee the entire production process, from raw material sourcing to final CNC cutting. This ensures a higher, more consistent standard of quality and full accountability.

The process is simple:

You provide a digital file: We work with standard industry formats like CAD files (.dwg, .dxf) or vector files (.ai, .eps).

We program our machines: Our technicians translate your design into precise cutting paths.

We execute with precision: The CNC router cuts, engraves, and bevels the EVA foam sheets with robotic accuracy.

Yes, absolutely. This is why you work directly with the factory. We are not just cnc routerint sheets; we formulate and produce the EVA foam itself. We can customize several key material properties:

UV Resistance: We can make it 3000 hours for markets with intense sun exposure, like Australia or the Middle East.

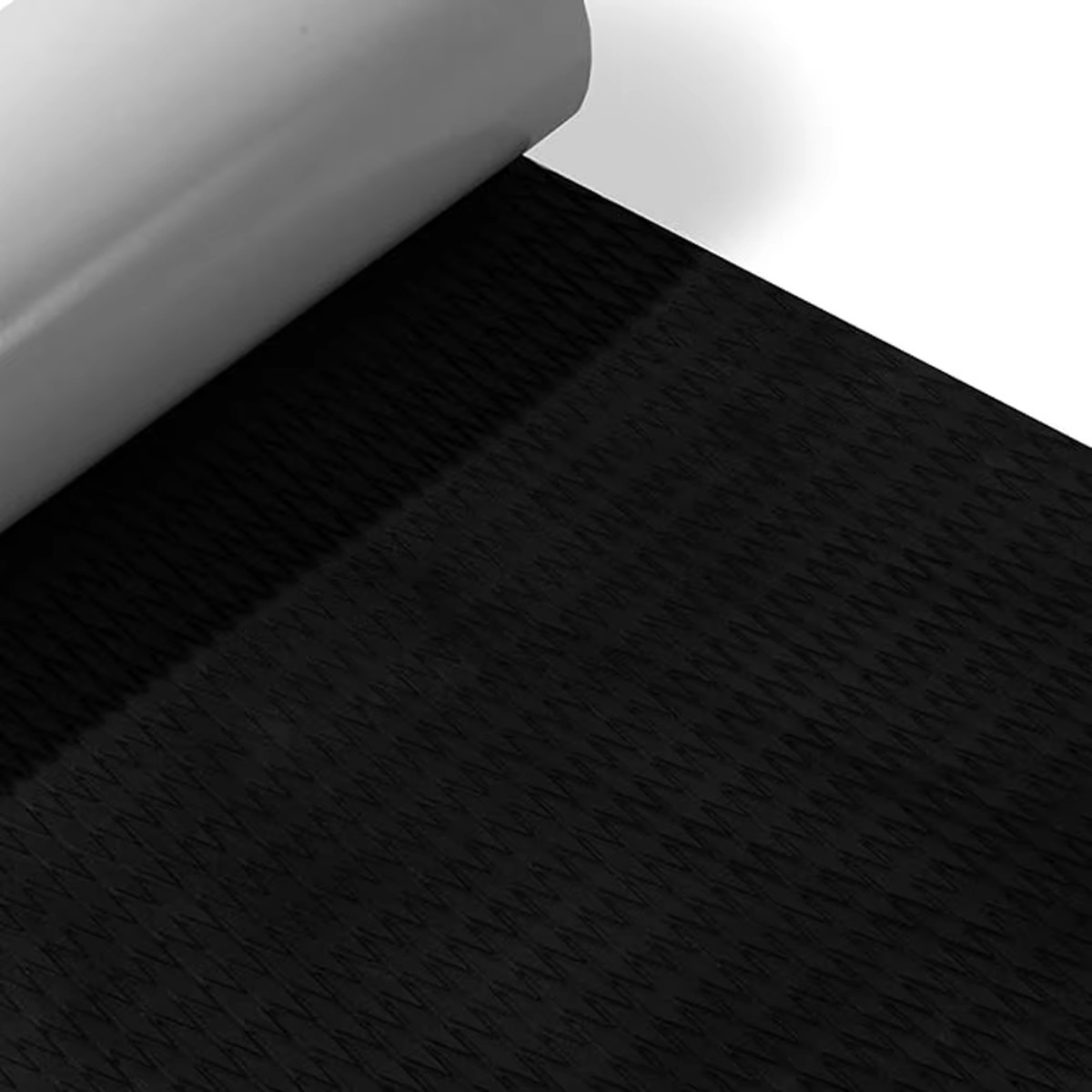

Density & Hardness: We can produce softer foam for enhanced anti-fatigue comfort or a denser, harder foam for commercial applications like cutting fish board.

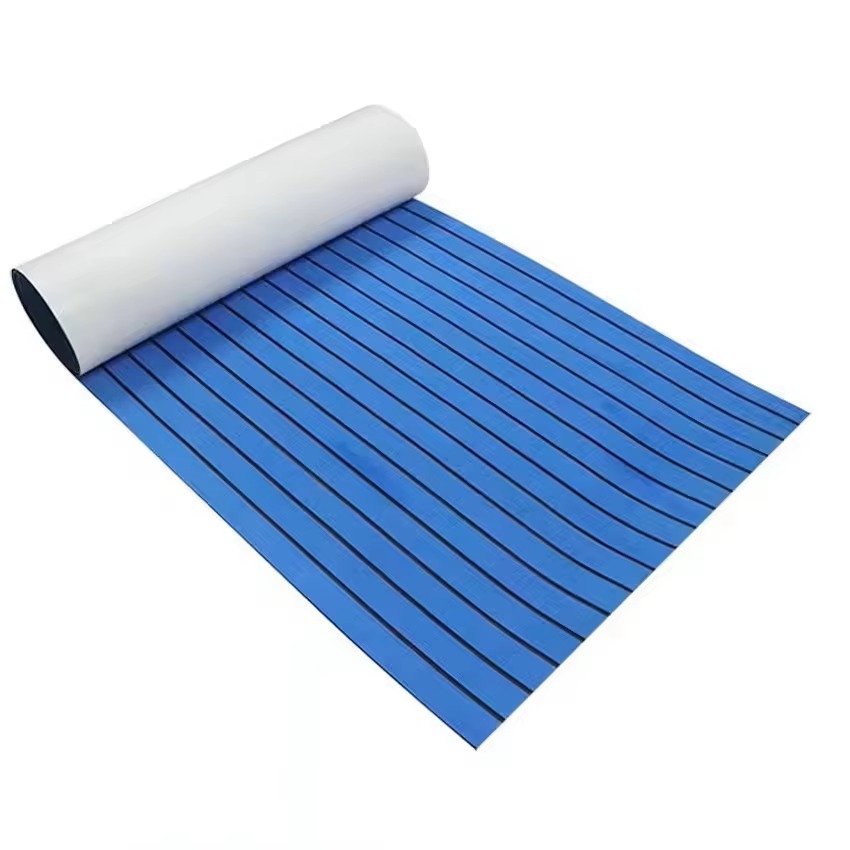

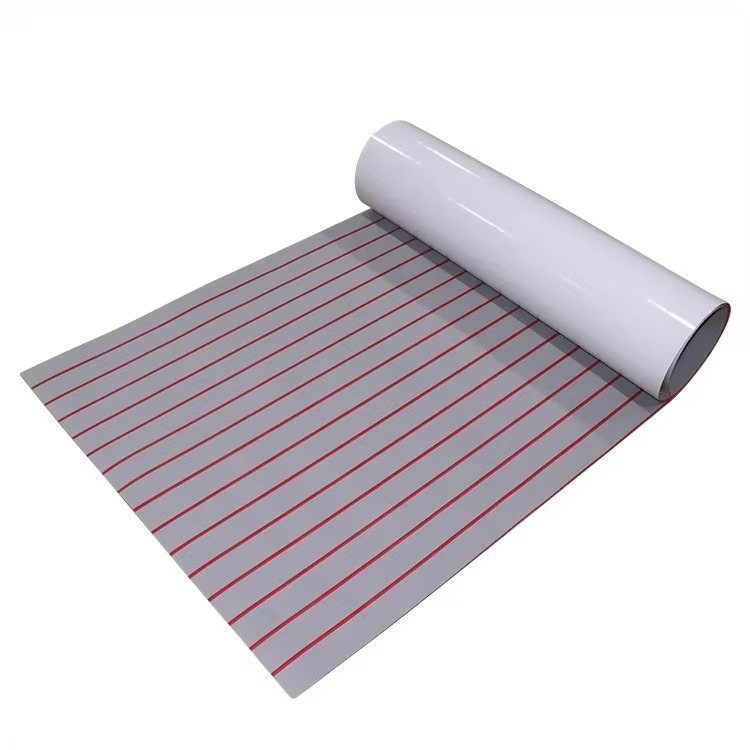

Color: We can create custom single or dual-layer color combinations to match a specific boat to your pantone color.

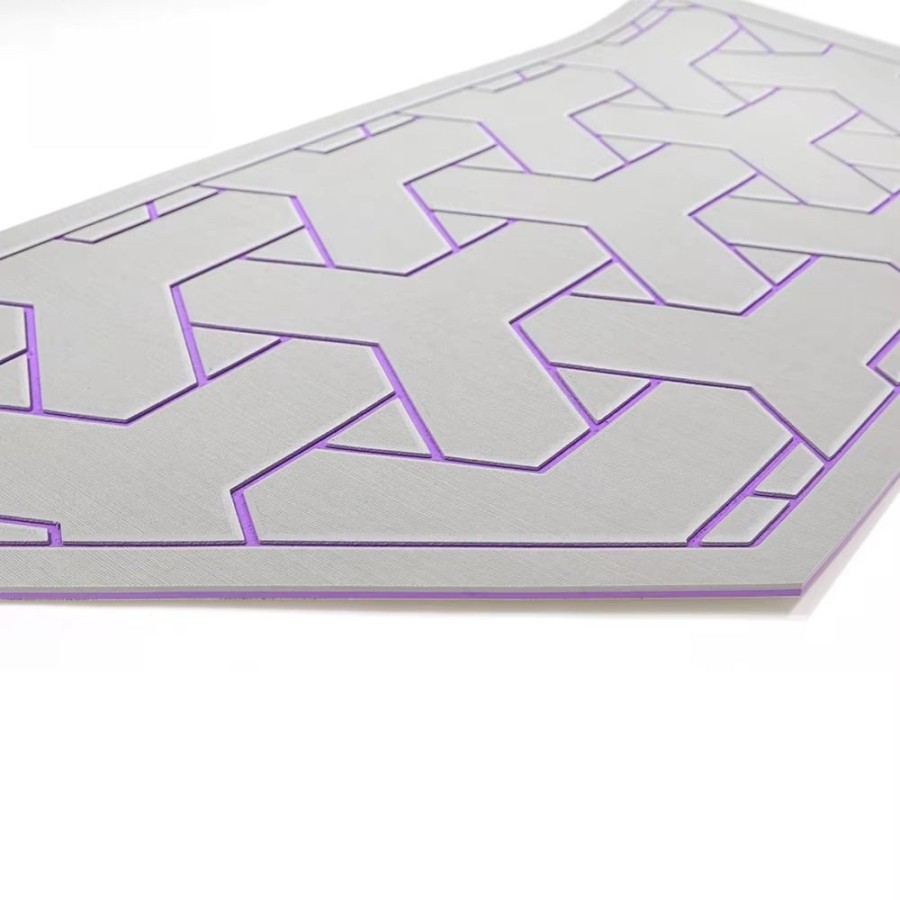

Texture: Beyond the standard brushed finish, we can develop custom embossed patterns for unique aesthetics and grip.

Get pricing: You send us your project requirements (design, material specs). We provide a detailed quote.

Design: You send us your digital file or templates or CAD files.

Sampling: For larger orders, we produce a sample from your file for you to test.

Mass Production: Upon approval, we begin mass production of your order.

Quality Assurance & Shipping: Every piece undergoes a final quality inspection before being carefully packaged and shipped to your designated port or warehouse.

Our MOQ is flexible and designed to accommodate different types of buyers, from small custom boatyards to large-scale importers.

For custom-cut kits: The MOQ is often based on a total square meterage or value, rather than a specific number of kits, making it easier for you to mix and match different boat models in one order.

For custom material formulation:100 pcs typically required to set up a new production run of a specific color or density.

Typical lead times are 2-4 weeks for production after sample approval. This can vary depending on order volume and complexity. We always provide a clear timeline with your quote.

The adhesive (PSA)is important. We exclusively use genuine 3M™ pressure-sensitive adhesive (PSA),for its good performance in marine environments. We often use 9775,99786 etc.Our quality assurance process includes:

Sourcing: We purchase only from authorized 3M™ suppliers.

Application Environment: The PSA is laminated in a temperature and humidity-controlled, dust-free environment.

Adhesion Testing: We perform regular peel tests to verify that the adhesive strength meets both 3M’s specifications.

Custom Foam Boat Flooring Ordering Process

Ordering custom foam boat flooring and decking from us is easy. With just six steps, you will get the best foam decking for your boats.

Get a Wholesale Quote

We provide free, no-obligation quotes based on your specific EVA foam requirements (quantity, dimensions, material specifications, customization). Click the "Get a Quote" button or contact our sales team directly.

Request Samples

After receiving your quote, we highly recommend ordering EVA foam samples to verify material quality, color, texture, and adhesive properties before placing your full wholesale order.orld.

Place Your Wholesale Orde

Once you're satisfied with the samples, confirm your order details (quantity, specifications, delivery address) with our sales team.

Production Begins

We start mass production upon confirmation of your order and receipt of payment. We accept various payment methods,,TT,L/C,PAYPAL.

Rigorous Quality Inspection

After production, our quality control team inspects all EVA foam products to ensure they meet our quality standards and your specifications before shipping.

Shipping and Delivery

Please inform our sales team of any shipping needs during the quoting process.We offer DDP,sea,train,and plane.

Custom Wholesale EVA Foam Boat Flooring Resources and Articles

We have provided a list of resources and articles about our custom foam boat flooring service and other services. The information offers information about production, how to choose and installation.

Boat Flooring Market Trends: A Tour of Global Boating Cultures

EVA foam sheets have become the preferred flooring material for small to medium-sized boats.

CNC Design File Prep for Custom Boat Decking

EVA foam sheets have become the preferred flooring material for small to medium-sized boats.

Choosing a Boat Flooring Supplier: 5 Keys to a Successful First Call

EVA foam sheets have become the preferred flooring material for small to medium-sized boats.

Get Started With Your Custom EVA Foam Marine Decking

We offer custom colors, textures, and logos and precise CNC routering by your CAD and templates to meet your exact specifications. Contact us for wholesale pricing.

Trend on Wholesale EVA Foam Boat Flooring

Below is a collection of resources providing information about our custom EVA foam products, including details on manufacturing processes, and other key considerations for wholesale orders.