10 Critical Questions to Ask Before Choosing Your EVA Foam Flooring Supplier

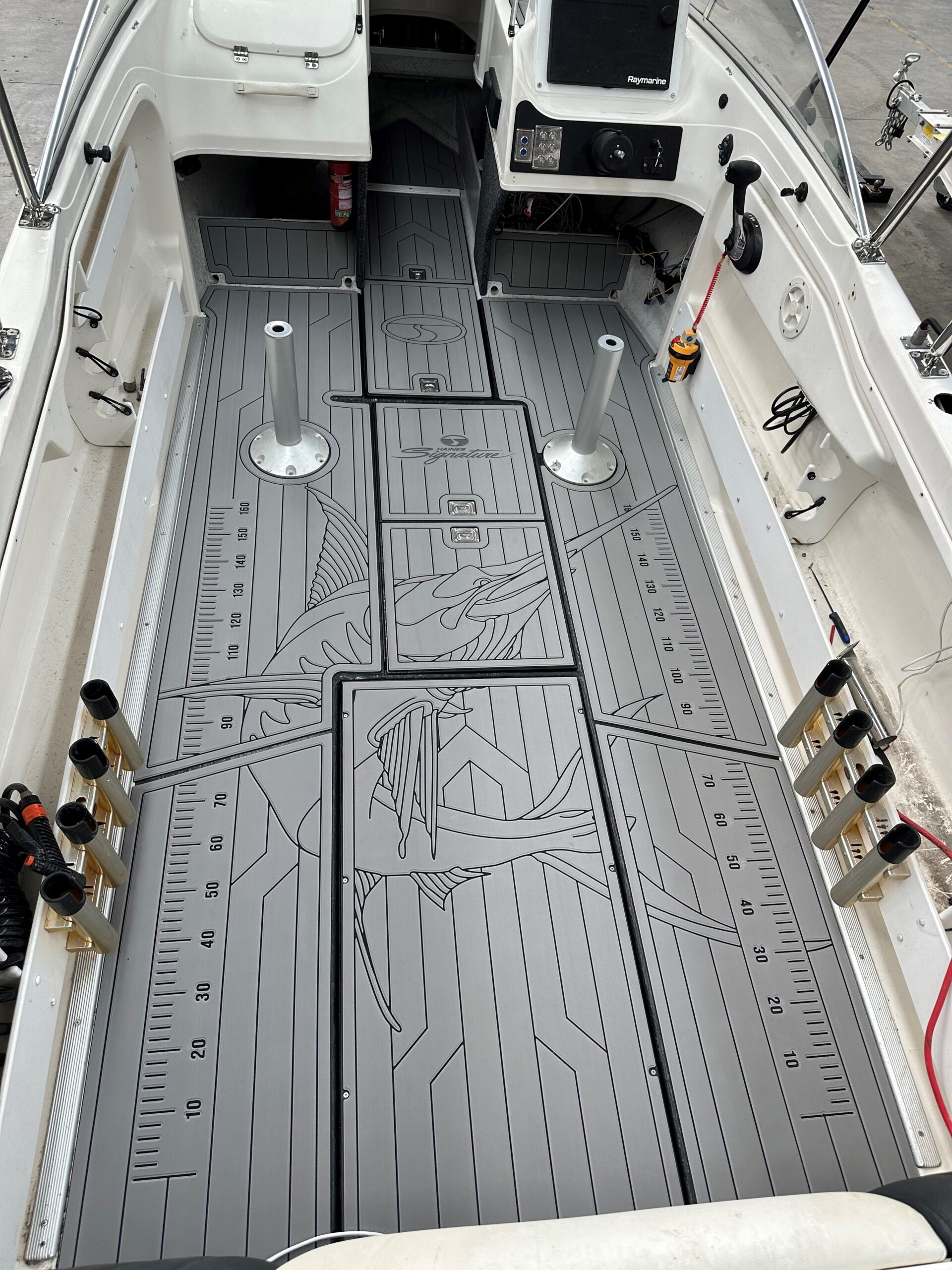

Imagine this: You’re on a boat in the Bahamas, under the hot midday sun. Suddenly, the deck starts peeling like wet cardboard. Sunscreen soaks into the cheap foam, sticky glue melts into a gooey mess at 122°F (50°C), and you have to scrub the floor with a toothbrush.

Here's a sad truth we see all the time: fixing bad EVA flooring is one of the most common—and annoying—repair jobs for boats less than 5 years old. The worst part? These problems could have been stopped if the owners had asked the 10 questions you’re about to learn.

Pull up this list on your phone right now and ask your supplier these hard questions. Unless you want to be the one paying $8,000+ next summer to rip up a bad floor.

1. "What is the density of your EVA foam, and is it a single-density or dual-density product?"

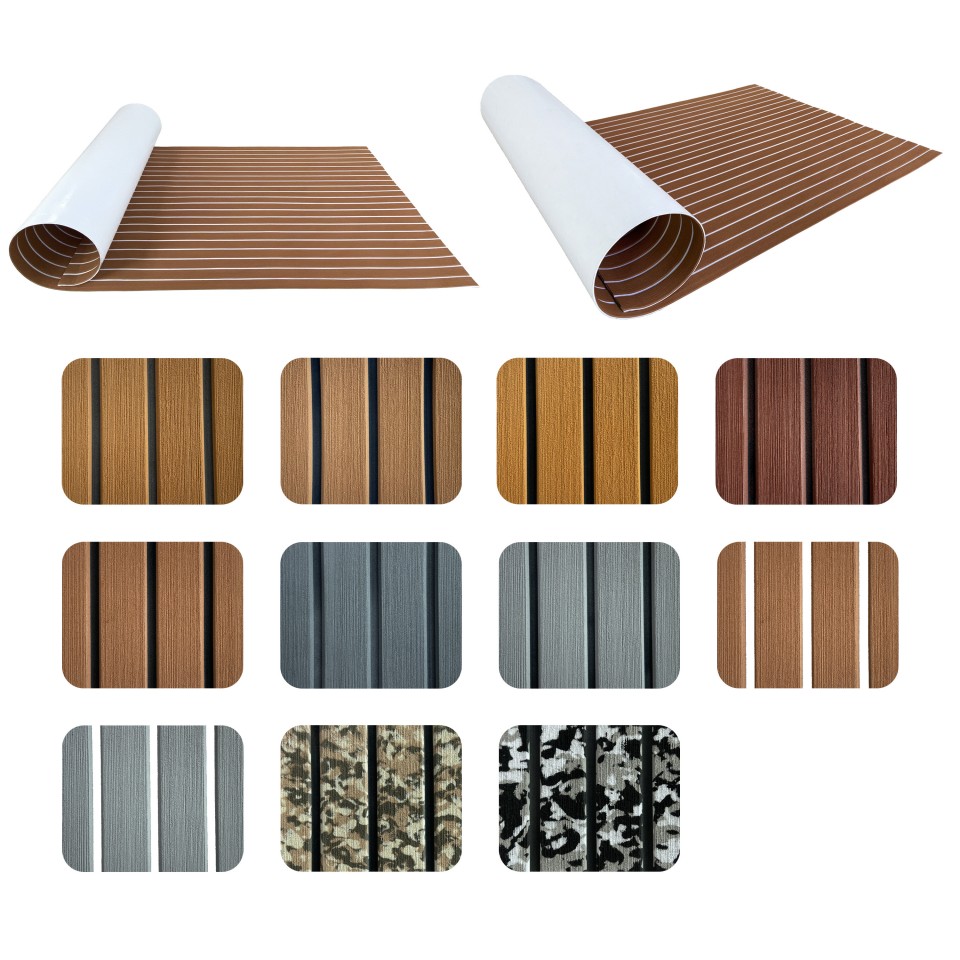

Why it matters: This is a pro-level question that helps you see what's real and what's just sales talk. All good boat foam is "closed-cell," but not all closed-cell foam is the same. Density—measured in kilograms per cubic meter (kg/m³)—is the sign of how long the foam will last and how good it will feel.

The Density Breakdown:

- Lower Density (for example, 80-120 kg/m³): This foam feels softer and more comfortable under your feet. But, it can get scratched or dented more easily by heavy things like coolers. It's a good choice for places where people don't walk much.

- Higher Density (for example, 180-220 kg/m³): This foam is much firmer and tougher. It's better at resisting hits, scrapes, and dents. This makes it perfect for busy areas on a boat. It just feels a little less soft.

- Dual-Density (The Pro's Choice): The best products often use a dual-density design. This means there is a tough, high-density top layer for strength, bonded to a softer, lower-density bottom layer for comfort.

What to demand: Ask for the material's density information. A professional supplier will have this ready on their technical data sheet. If they don't know their own product's density, they are just a reseller, not a maker. This one question shows you who you're really dealing with.

2. "What is the QUV accelerated weathering rating of your material?"

Why it matters: Every supplier will say their product is "UV-resistant," but that means nothing without proof. The sun's UV rays don't just fade color; they break down the foam, making it chalky, weak, and cracked over time. The professional way to measure this is with a QUV Accelerated Weathering Test.

In this test, samples are put in a machine that hits them with strong UV light and cycles of wetness. This copies years of being outside in just a few weeks. How well it does is measured in hours.

Understanding the Hours (More is Better):

- Standard Grade (about 1000 Hours): This is okay for many outdoor products. It offers good protection but might start to fade in a few years in sunny places.

- Professional Grade (about 2000 Hours): This shows a strong product with high-quality UV blockers (like HALS). It's made to resist fading and breaking down for a long time.

- Premium / Architectural Grade (3000+ Hours): This is the best you can get. It means the foam has top-of-the-line UV protection to keep its color and strength for the longest possible time.

What to demand: Ask this direct question: "Can you provide a third-party test report showing your material has passed a 2000-hour or 3000-hour QUV weathering test (ASTM G154)?"

A top-level maker who cares about quality will have this information and be happy to share it. A supplier who can't show you a QUV test report is asking you to trust them without any real proof.

3. "Can you verify the brand and model of your adhesive, and can you provide a sample for testing?"

Why it matters: When it comes to EVA decking, the adhesive (the sticky backing) is where suppliers often use cheaper materials. This can lead to disaster. A supplier might say they use great 3M™ adhesive, but is it the real thing or a cheap fake? The reason decks peel is adhesive failure. You need proof, not just promises.

The best choices for this job are specific models from 3M. Two of the most trusted are:

- 3M™ 9080A: A strong, all-around adhesive known for its great bond.

- 3M™ 9775WL: Another top choice, known for sticking well to many surfaces.

The Ultimate Way to Check: The Sample Test

Don't just trust a piece of paper. The only way to know for sure is to test it.

Here’s what you demand:

"Can you send me a small, labeled sample of your EVA foam with the exact adhesive backing you use on your final product, so I can test the bond myself?"

A supplier who is sure of their quality will gladly send you a sample. A supplier who is not being honest will likely make an excuse.

How to Test the Sample:

- The "Look and Feel" Test: Real 3M™ liners often have the 3M logo printed on them. The adhesive should feel very sticky, but clean.

- The "Sacrificial Bond" Test: Find a clean, smooth spot on your boat. Peel the liner off and press the sample down firmly for 15-20 seconds.

- The "Morning After" Test: Let it sit for 24 hours. This lets the adhesive get much stronger. Now, try to peel it off.

- A premium adhesive will be very hard to remove. The foam might even tear before the bond fails.

- A cheap adhesive will often peel off much more easily, sometimes leaving a sticky mess behind.

This simple test tells you everything about the most important part of your new deck.

4. "How do you ensure a perfect fit? What is your cutting technology?"

Why it matters: A deck that doesn't fit well looks bad and lets water get underneath. The difference between a perfect, factory look and ugly gaps is all about precision. We often see big fit problems that come from suppliers using bad, hand-drawn templates.

Make sure your supplier uses modern methods:

- Digital Templating: They should use 3D scanners or a computer library of boat models, not just a plastic sheet.

- CNC (Computer Numerical Control) Cutting: This technology uses a computer to guide the cutter, making perfect shapes around all the items on your deck.

What to demand: Ask for a sample cutout from another job. Hold it. Is the edge perfectly smooth? Does it feel like a high-quality product? The sample will tell the truth.

5. "What type of UV stabilizer do you use, and can you provide the test report?"

Why it matters: The sun is always beating down on your deck. Without strong protection inside the foam, the color of your new deck can fade to a chalky mess in just a few years. This isn't just about looks; it means the foam itself is breaking down. The only thing that stops this is the quality of the UV blockers mixed into the foam.

What to demand beyond a simple answer:

- Specify the Chemical Type: Don't accept vague answers like "it's UV-treated." Ask them to confirm they use a high-performance HALS (Hindered Amine Light Stabilizer) package. This is the pro standard and shows you know your stuff.

- Demand the Performance Data: The most important step is to ask for proof. The professional standard for measuring this is an accelerated weathering test (QUV).

The Killer Question: "Can you provide a copy of a third-party test report, like an ASTM G154 (QUV) test, that shows your material's performance after at least 2000 hours of exposure?"

Interpreting the Result:

- A "Pass" at 2000+ hours means it's a premium, professional product made to last for years.

- A report showing only 1000 hours means the protection is standard, but not the best.

- No report at all? This is the biggest red flag. It means the supplier is either using a cheap, untested product or they have no idea how it will perform.

A supplier's ability to give you this specific test data says a lot about their quality.

6. "Can you provide third-party certifications for product safety and ethical production?"

Why it matters: A professional supplier sells peace of mind, not just a product. They prove this with tests from independent, third-party companies. These tests check that the product is safe and that the company is fair and ethical.

Key Certifications to Demand:

- Material Safety (RoHS Compliance): This is a must-have. It promises the foam is free from harmful things like lead and mercury. It's a promise that the product is safe for you and the water.

- UV Durability (ASTM G154 / QUV Test): This is the ultimate proof of how the foam will hold up against the sun. In this test, the material is put in a special machine that copies years of harsh sun and weather. It proves the foam won't just fade, but that it will also resist getting weak, brittle, or chalky over time. It's the key certificate for long-term performance.

- Ethical Sourcing (BSCI Report): This shows that the company treats its workers fairly and has a safe workplace. It's a key sign of a responsible partner.

Real-world Impact: Imagine a guest on your boat slips on a wet deck. Your insurance might ask for papers that prove your decking material is safe. If your supplier can't give you that certificate, you could have a big problem.

7. "What is your realistic lead time from final design approval to delivery?"

Why it matters: In boating, timing is everything. A two-week delay can mean missing a weekend on the water. It’s key to understand the supplier's whole timeline, not just their "fast shipping" ad.

Typical Timelines for Custom Orders:

- Domestic (US-based) Suppliers:

- Production Time (Post-Approval): Typically 2 to 4 weeks.

- Shipping: 3 to 7 business days.

- Total Estimated Time: Approximately 3 to 5 weeks.

- Direct from Overseas Suppliers:

- Production Time (Post-Approval): Typically 2 to 4 weeks.

- Shipping (by sea): Sea freight from Asia to the US typically takes 3 to 6 weeks. Express services may shorten this to around 15 to 20 days.

- Total Estimated Time: Approximately 5 to 10 weeks.

Important Note: Sea freight times can change. It's always best to check shipping details with your supplier.

8. "What is your pricing structure for bulk or wholesale orders?"

Why it matters: Whether you are a boat builder or friends buying together, knowing how a supplier handles large orders is key to getting the most for your money. The price often goes down when you order more.

Don't just ask "what's your best price?" Instead, ask smart questions:

- "What is your MOQ (Minimum Order Quantity) for wholesale pricing?"

- "What are your price tiers? For example, what is the per-sheet or per-square-foot cost for orders of 10+, 50+, and 100+ sheets?"

- "Does the price include adhesive backing, and if so, what brand is it?"

- "Can you provide a few samples for quality evaluation before a bulk order?" A supplier who is sure of their product will almost always agree.

Negotiation Tip: Present yourself as a possible long-term partner, not a one-time buyer.

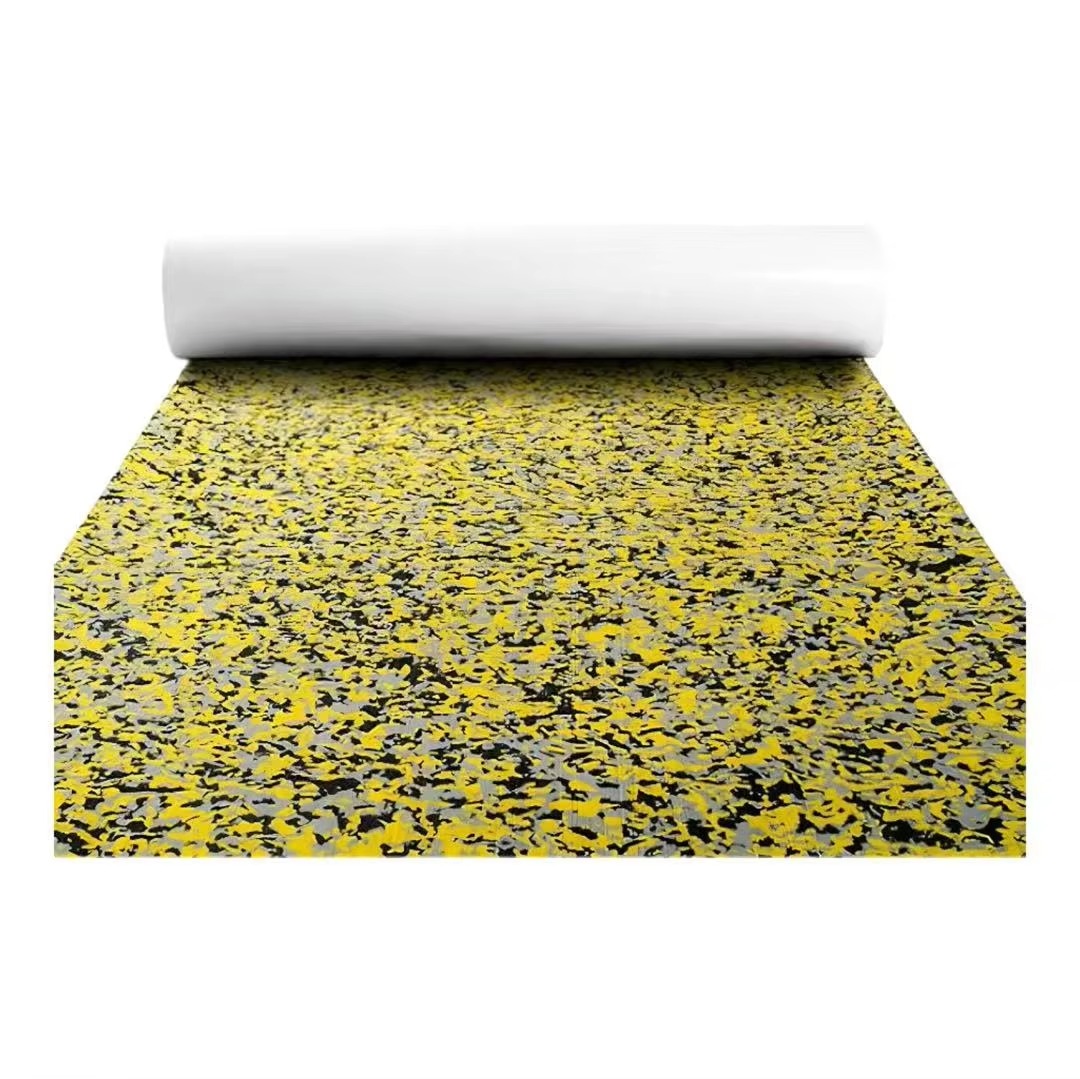

9. "How are your dual-color foam sheets stuck together, and can you promise they won't peel apart?"

Why it matters: This question is about how two-color EVA foam is made. A huge problem is called delamination—that’s when the top color peels away from the bottom color. It can start as a small bubble and then spread, turning a beautiful deck into a peeling mess. This usually happens when the layers are just glued together.

The Manufacturing Difference (The Pro's Secret):

- Bad Way (Adhesive Lamination): This is the cheap way. Makers just take two foam sheets and use glue to stick them together. The glue is a weak spot. Heat, sun, and water can make the glue fail easily.

- Good Way (Thermal Bonding): This is the best way. A real maker uses a special process with high heat and pressure. Think of it like making a grilled cheese sandwich—the layers are melted together to become one single, solid piece. There is no extra glue. The bond created is super strong, as strong as the foam itself.

The Killer Question & The Physical Test:

First, ask the supplier directly: "Do you use thermal bonding, or do you use a separate glue to stick your dual-color sheets together?"

Then, demand proof. Ask for a small sample of their two-color material and do this simple test:

- Take the sample and try to peel the two layers apart at a corner.

- The Result You Want (Thermal Bond): You won't be able to separate the layers cleanly. The foam itself will stretch and eventually tear before the layers come apart. You are ripping the foam, not just peeling apart a seam.

- The Red Flag (Adhesive Lamination): You will be able to peel the two layers apart. If you can separate the two colors along a glue line, you have found a low-quality product.

How a supplier joins their foam is a clear sign of their quality. A thermally bonded product is made to last.

10. "How do you package and ship large sheets to prevent permanent creases or damage during transit?"

Why it matters: This question uncovers a supplier's true commitment to quality, right up to your doorstep. Imagine waiting weeks for your custom decking, only to open the box and find a deep, permanent crease running right through the middle of the main sheet because it was folded tightly to save a few dollars on shipping. EVA foam has "memory"; a bad fold during a long transit can become a permanent scar that will never fully relax out.

A supplier's packaging strategy is a direct reflection of their professionalism.

What you need to distinguish between:

- The Red Flag (Folded in a Box): This is the amateur, cost-cutting method. The supplier folds the foam sheets like a blanket to fit them into a smaller, cheaper-to-ship square box. This almost always leaves hard, permanent creases at the folds, rendering parts of the sheet unusable and looking terrible. It places all the risk on you.

- The Professional Standard (Rolled, Never Folded): A professional supplier will always ship their material rolled, never folded. The foam is carefully rolled (often around a supportive cardboard core) and placed into a long, rectangular box. This method prevents hard creases and allows the foam to be easily flattened before installation. It is the accepted industry standard for quality.

- The Premium Method (Shipped Flat): For very large, complex, or high-value custom-cut kits, the absolute best suppliers will offer the option to ship the entire kit flat in a custom-built, low-profile wooden or heavy-duty cardboard crate. This is the ultimate sign of a first-class operation. It costs more, but it guarantees the product arrives in absolutely perfect, ready-to-install condition.

The Ultimate Litmus Test: Be direct and specific with your question.

Don't just ask if the shipping is "safe." Ask them point-blank: "Will my sheets be shipped rolled in a long box, or will they be folded? Can you send me a photo of your typical packaging?"

A professional supplier will immediately confirm they only ship rolled or flat and will be proud to show you their robust packaging. A supplier who folds their foam is telling you everything you need to know about their quality standards.

Now You're Equipped. The Next Step is Yours.

Armed with this 10-point checklist, you're no longer just a customer—you're an informed buyer who can demand proof, identify quality.

The only challenge now is finding a supplier who welcomes this level of scrutiny.

We Wrote the Checklist Because We Live By It

We created this guide because these questions are the foundation of our business. At Foam Boat Flooring, we aren't resellers; we are the direct-source factory, and our process is designed to pass every test you just learned:

- When you ask for our QUV test reports, we'll send you the data proving our materials withstand 3000+ hours of weathering.

- When you demand a sample to test our genuine 3M™ adhesive, we'll gladly ship one to you.

- When you ask about our lamination, we'll explain our thermal bonding process and send a sample we know you can't peel apart.

- And when you need a replacement piece two years from now, your original design file will be archived and waiting.

Partner with the Source

Your search for a trustworthy, professional-grade supplier ends here. Why settle for a reseller when you can partner directly with the factory that embodies these standards?

Put our promises to the test. Contact our expert team for a no-obligation, factory-direct quote and let's give your boat the durable, high-performance deck it deserves. See the quality for yourself and start your project today at:

https://foamboatflooring.com/