How to Prevent and Restore Faded EVA Foam Boat Decking

Is Your EVA Foam Deck Fading? Here’s Why It Happens and How to Prevent It

There's nothing quite like the look of a brand new, vibrant EVA foam deck. It's clean, modern, and makes your whole watercraft feel fresh and luxurious, enhancing the entire boating experience. Yet after a season or two out on the water, you may observe something discouraging: the once-rich color has actually begun to look dull, washed-out, and tired. Fading and discoloration is one of the most typical aggravations for any boat owner, turning a beautiful investment right into an aesthetic frustration. You begin to wonder, "Is this normal? Did I do something wrong? And most importantly, can it be repaired?"

The short response is yes. Fading isn't just bad luck; it's a foreseeable result of details ecological elements attacking lower-quality materials. In this article, we'll study the scientific research behind why boat deck foam fades and, a lot more notably, provide you with a clear guide on just how to stop it from occurring to your boat.

The Main Cause of Fading: How UV Rays Affect Your Foam Boat Deck

The main factor your watercraft's outdoor decking fades is the same reason a newspaper left in the sunlight turns yellow and weak: ultraviolet (UV) radiation. The sun releases a broad spectrum of energy, including the noticeable light our eyes can see. But it likewise emits an effective, unseeable component called UV radiation. Think of this as a high-energy pressure within sunlight. Unlike noticeable light, UV radiation has adequate power to literally strike and break down the chemical bonds that hold man-made materials with each other.

EVA (Ethylene-vinyl acetate) foam is a polymer, which suggests it's made from long, duplicating chains of molecules. The shade you see originates from pigment molecules blended into these chains. When UV rays strike your deck, a process called photodegradation occurs: high-energy UV photons imitate small molecular ravaging rounds, collapsing right into and breaking the chemical bonds that provide the pigment its color. As these particles are broken down, they shed their ability to reflect light correctly, creating the lively color to discolor. This UV strike doesn't simply impact the color. In time, the same photodegradation procedure that destroys pigments likewise damages the EVA polymer chains themselves. This can cause a loss of flexibility, causing the foam to really feel even more weak, end up being chalky to the touch, and even establish surface area cracks.

Beyond the Sun: Other Factors That Can Discolor Your Decking

If all EVA foam is prone to UV damages, why do some decks last for several years while others fade in a solitary season? The answer lies in the top quality of the raw product and, crucially, the ingredients that are mixed into it during manufacturing. This is especially true in a harsh marine environment.

Lower-cost EVA foam usually has more "fillers"-- less expensive substances mixed in to raise bulk and lower cost. These fillers can be much less steady and might respond negatively to UV direct exposure, speeding up the degradation process. Furthermore, higher-density eva foam boat decking typically has a more snugly packed molecular structure, making it naturally much more durable.

Proactive Protection: 5 Proven Ways to Prevent Fading

Armed with this knowledge, here are the most effective, real-world strategies to keep your deck looking vibrant for years to come. True UV protection starts with smart habits.

1. Cover Your Boat

This is conveniently the easiest and most efficient kind of prevention, based upon a direct principle: if UV rays can not reach the deck, they can not cause damage. While premium EVA foam is developed to stand up to the sunlight, literally obstructing it completely gets rid of the danger. Make it a habit to use a high-quality boat cover when it's not in active usage, especially during the peak sun hours. This might imply using a full boat cover, deploying a bimini top if you're anchored for a long lunch, or storing the boat in a covered slip. This simple act can dramatically extend the life and vibrant color of your flooring.

2. Regular Cleaning with the Right Products

Think about your deck's surface like your very own skin; what's left on it can trigger damage over time. Salt crystals, dust, and even bird droppings, when left to bake in the sunlight, can act like little magnifying glasses, concentrating the sun's intense rays onto small areas and producing "hot spots" that accelerate UV damages. A simple cleaning routine is your ideal defense against this. For detailed instructions, please see our complete guide on cleaning your boat deck. Just as important as what you use is what you don't use. Absolutely avoid harsh chemicals. Products containing bleach, ammonia, or acetone are the enemies of EVA foam as they can destroy its built-in defenses.

A Step-by-Step Guide to Restoring a Lightly Faded Deck

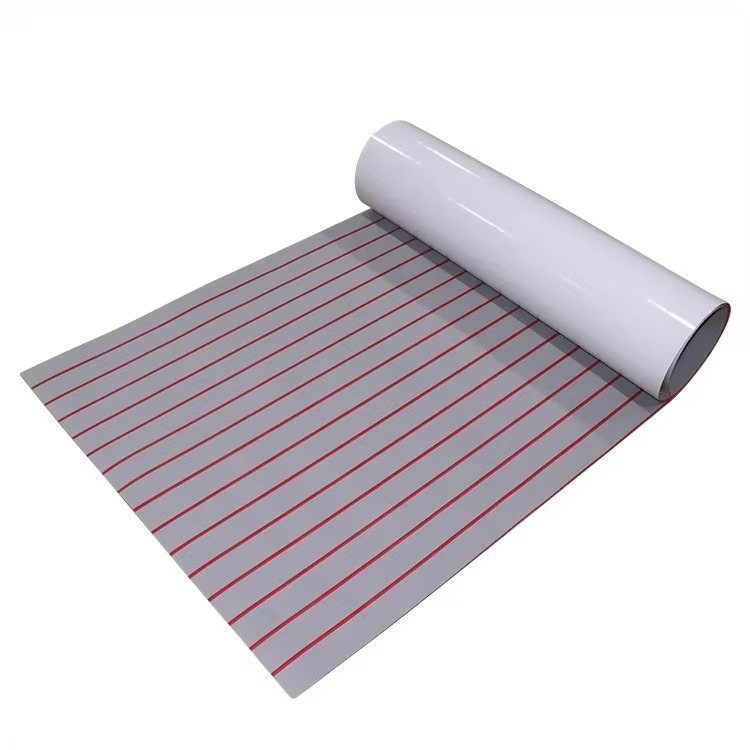

For watercraft proprietors that intend to take their deck's defense to the following degree, applying a high-quality UV protectant spray can be a useful component of an upkeep routine. Think of this as using a high-SPF, leave-in conditioner for your EVA foam. Renowned items in the marine sector, such as the well-regarded 303 Marine Aerospace Protectant, are specifically developed for this purpose.

These sprays function by leaving a clear, non-greasy, tiny film on the foam's surface. This film serves as a temporary barrier, designed to take in the force of the UV radiation so the foam below does not need to. This can help to maintain a rich shade and a soft feel.

However, it is critical to understand the limitation of this approach. A protectant spray is a maintenance supplement, not a cure for poor material. If the foam itself was manufactured without built-in UV stabilizers, it is inherently unstable. A topical spray can not quit this inner degradation. Therefore, use these sprays as an effective device in your upkeep toolbox, but remember they work best when applied to a high-grade foam from the very start.

Choosing for Longevity: Why UV-Resistant EVA Foam Matters

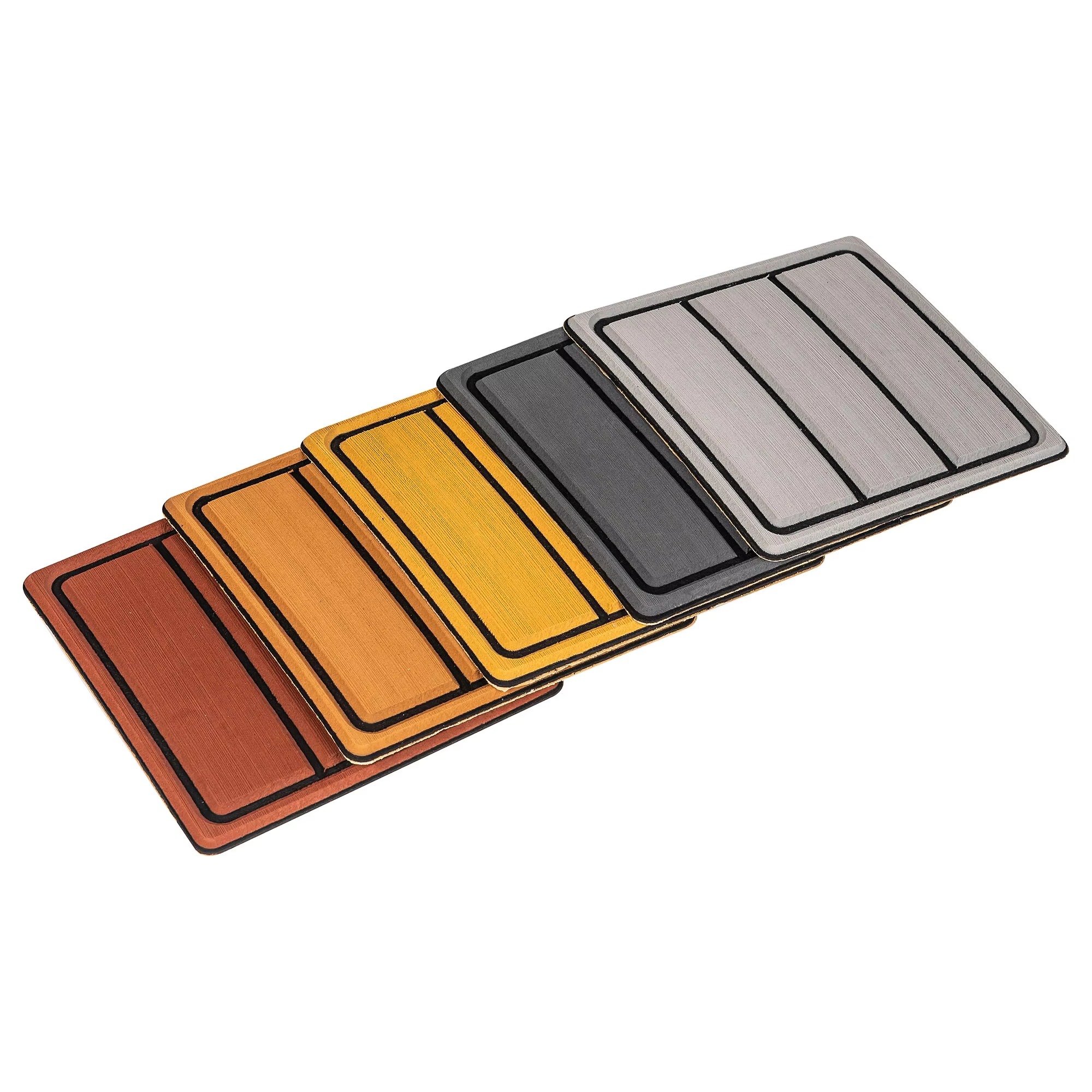

This is where the battle is won. No amount of after-care can make up for poor-quality material. Before you purchase any foam decking for boats, it is essential that you become an informed buyer. Ask the manufacturer direct questions: "Is your EVA foam manufactured with high-grade UV stabilizers blended directly into the raw material?" A reputable distributor will be able to answer these concerns clearly.

The single largest consider your deck's long-term color stability and durability is the quality of the raw products and, most significantly, the premium UV stabilizers blended right into its core. By choosing a premium, UV-stabilized foam boat decking from the start, you are not just getting a color; you are investing in color that lasts. You are investing in comfort and the long-lasting appeal of your vessel.

Foam Boat Flooring is devoted to just that. We are a factory-direct supplier that relies on using just superior EVA materials infused with the highest-grade UV inhibitors. Our team believe your investment in foam for a boat should stand up to the sun and the test of time. If you're tired of worrying about fading and want a flooring solution built for durability, contact us today. Let's build you a deck that stays vibrant, season after season.